Welcome to our websites!

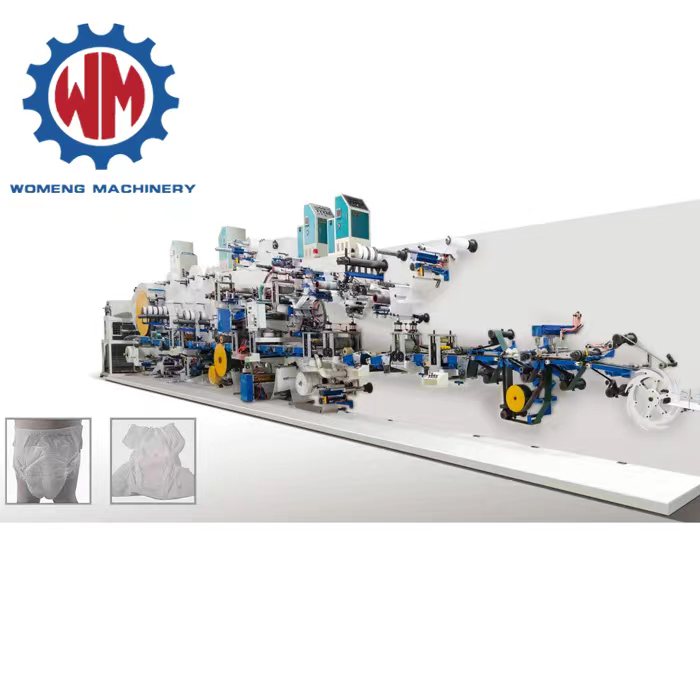

Small Scale Baby Diaper Making Machine Production Line Full Automatic Diaper Manufacturing Machine

Small Scale Baby Diaper Making Machine Production Line Full Automatic Diaper Manufacturing Machine

Baby Diaper Making Machine

The diaper making machine is suitable for manufacturing kinds of diaper shapes with different raw materials for baby or adult. Outputted products: Baby Diaper with different shapes (T shape, I shape, pull up pants etc) and different sizes: NB, S, M, L, XL, XXL.

|

Configuration

|

|

|

Product size

|

380x280mm, 420x320mm, 480x320mm, 520x340mm

|

|

Safety system

|

Safety guard installed at the operating side, with security identifier, emergency stop switch at per segment, Driven side is equipped with the radiator system and safety wire.

|

|

Control system

|

PLC control system,Operating on the touch screen,Configure HDTV monitor.

|

|

Materials corrective system

|

Germany BST automatic web guide system (optional).

|

|

Drive system

|

Full servo drive, digital size change, ensure, run synchronized at full process. The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase.

|

|

Product structure

|

Top(bottom) tissue paper, sap core, ADL, hydrophobic NW(leg cuff), topsheet NW, PE film, spandex, frontal tape, elastic nonwoven(zero-waste),S cut.

|

|

Tension system

|

Tissue paper, cotton core (SAP), Top sheet nonwoven, ADL,PE film,back&wing release paper,packing film A&B shaft unwinding by Inverter motor.

|

|

Packing way

|

Auto stacker as customized design (one push two exit.)

|

Write your message here and send it to us