Semi Full Servo Automatic Second Hand Used Underpad Under Pad Sanitary Napkin Adult Baby Diaper Production Line Making Machine

Semi Full Servo Automatic Second Hand Used Underpad Under Pad Sanitary Napkin Adult Baby Diaper Production Line Making Machine

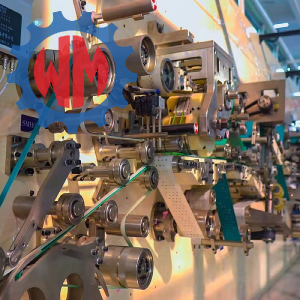

1. Main technical parameters:

Configuration

Product Structure Carrier Tissue, Fluff Core (Mix with SAP), Topsheet(3-PCS structure), ADL, Backsheet, Back Release Paper, Wings Release Paper, Pouch Film

Product Size Daytime use: 240mm

Night use: 285mm (Customized Design)

Control System PLC Programming control, HMI operation

Tension System Carrier tissue, absorbent paper, topsheet N.W., leg cuffs N.W., ADL, PE film, Back release paper, Wings Release Paper, pouch film

A&B shaft active unwinding by inverter motor

Drive System Full servo drive. Using import conveyor and timing belt. Important Part using import bearing.

Safety System Safety guard installed at the operating side, equipped with emergance stop switch, security identifier. Driven side is equipped with safety pull wire

Materials corrective system Germany BST automatic web guide system (optional)

2. Functions of the main machine:

1:High speed crusher: 450kgs/hour, can crush treated and untreated pulp.

2:Timing belts for driven system

3:Fluff pulp forming drum. It can produce both fluff pulp type and ultra-thin type sanitary napkins with quick-easy

package.

4:Main raw materials automatic tension controlling, automatic unwinding and splicing, auto rejection system

forunqualified products, 3 sets auto web guider system. (used for surface nonwoven, PE film and air laid

paper and tissue paper)

5: 5sets Web guider

6:waste raw materials collection device

7: It can be controlled remotely which is convenient for maintenance and solve programs problems.

8:Except glue, all the other raw materials have missing detection function, connection detection and auto

rejection function.

9:SAP mixed with fluff pulp feeding device

10:Quick-easy inner packing type

11: One set touchable screen, switch on/off, running speed, time, counting pieces, parameter setting, alarm,

error display, error enquiry (functions setting appear on screen are different according to different machine type).

12:Safety shield using aluminum alloy frame, toughened glass.

13:Glue applicator bridge structure set on the front of the machine.

At present, we have cooperate customers:

Bangladesh, Russia, Indonesia, United States, Korea, Pakistan, Mauritius, Myanmar, Russia , Taiwan,

Hong Kong , Ghana, Albania, Sain, Morocco, Egypt, Ethiopia, Poland, Nigeria, Poland,

Libya Spain, Cameroon, Uganda, Bosina and hergegovina, Vietnam ….