Welcome to our websites!

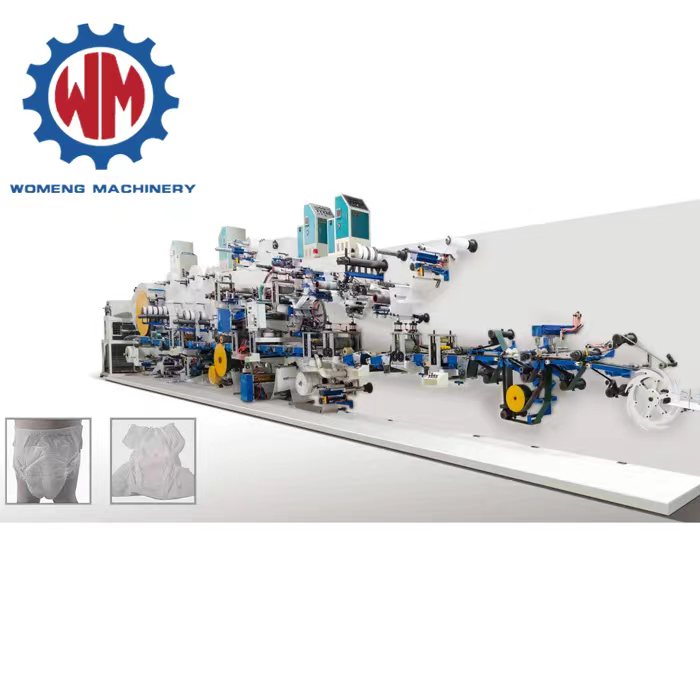

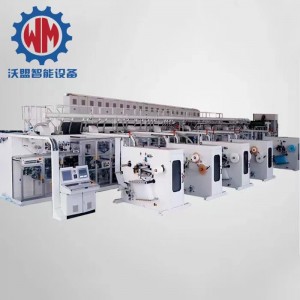

Machine For Manufacturing Baby Diaper Making Production Line

machine for manufacturing baby diaper making production line

Product Overview

machine for manufacturing baby diaper making production line

Adopt several servo motors for transmission controlling, main raw materials unwinding driven by servo control, to

guarantee the precision and stability of the machine in high speed, and can realize not change any transmission parts to change the product’s size, can directly set on PLC, easy to operate and maintain

guarantee the precision and stability of the machine in high speed, and can realize not change any transmission parts to change the product’s size, can directly set on PLC, easy to operate and maintain

PRODUCT SPECIFICATIONS

|

1

|

Design speed

|

600pcs/min

|

|

2

|

Stable working speed

|

500pcs/min

|

|

3

|

Qualified rate

|

≥ 97%

(exclude the wastage due to the glue applicators and materials splicing joint) |

|

4

|

Efficiency

|

≥ 85%

|

|

5

|

installation capacity

|

≥240KW

|

|

7

|

Electricity

|

380V ±5%、50HZ

|

|

8

|

Wire

|

Three phases four wires 380V/50Hz (ground wire) 3X120mm³+1X50mm³+1X25mm³

|

|

9

|

Air pressure

|

≥0.8Mpa 2.6m³/min

|

|

10

|

Total weight

|

About 78tons

|

|

11

|

Machine size

|

32×8×5 M(L×W×H)

|

|

12

|

Working space

|

38×12×8 M (L×W×H)

|

|

13

|

Machine color

|

Rice white ,can be changed by order

|

|

14

|

Product size

|

S,M,L,XL

|

|

15

|

Containers

|

6X40HQ

|

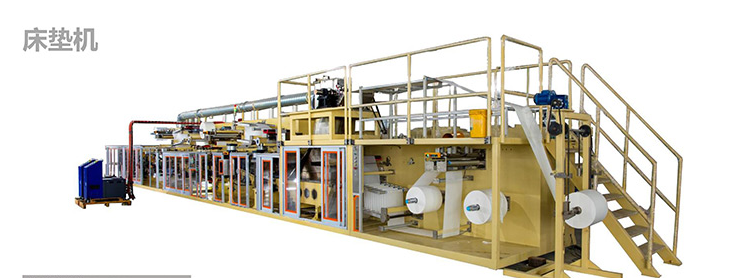

PRODUCT CONFIGURATION

1.Machine frame structure and main characters : Reasonably solid square steel frame

2. Crusher system3. Fluff forming system4. SAP feeding system

2. Crusher system3. Fluff forming system4. SAP feeding system

5. Bottom tissue feeding, roll diameter φ800mm

6. Upper tissue, roll diameter φ800mm

7. Fluff core wrapped by upper and bottom tissue, also can be wrapped by one whole piece tissue

8. ADL feeding, roll diameter φ800mm

9. Fluff core inner cut device 1 set,adopt frame type structure, increase the cutter life

10. Leak cuff unit

11. Hydrophilic nonwoven supply, roll diameterφ800mm

12. Side tape supply:

13. Elastic ear material supply unit

14. Frontal ear material supply

15. Three pieces complex, two sides fixing unit, adhesion pressing

16. Bottom film supply

17. Frontal tape supply

18. Surface layer, absorption core, bottom film pressing19. One set products cutting unit

20. 1set pressing unit(Y shape roller360)

21. Product vertical tri-fold

22. 1 set pressing unit(Y shape roller 200)

23. Transmission unit

24. 1 set final cut unit

25. Horizontal fold transmission unit

26. 2 set horizontal fold unit

27. Product transmission unit

28. Auto rejection exit (pneumatic)

Write your message here and send it to us