High Efficiency Full Servo Baby Diaper Manufacturing Machine Global Export

BENEFITS :

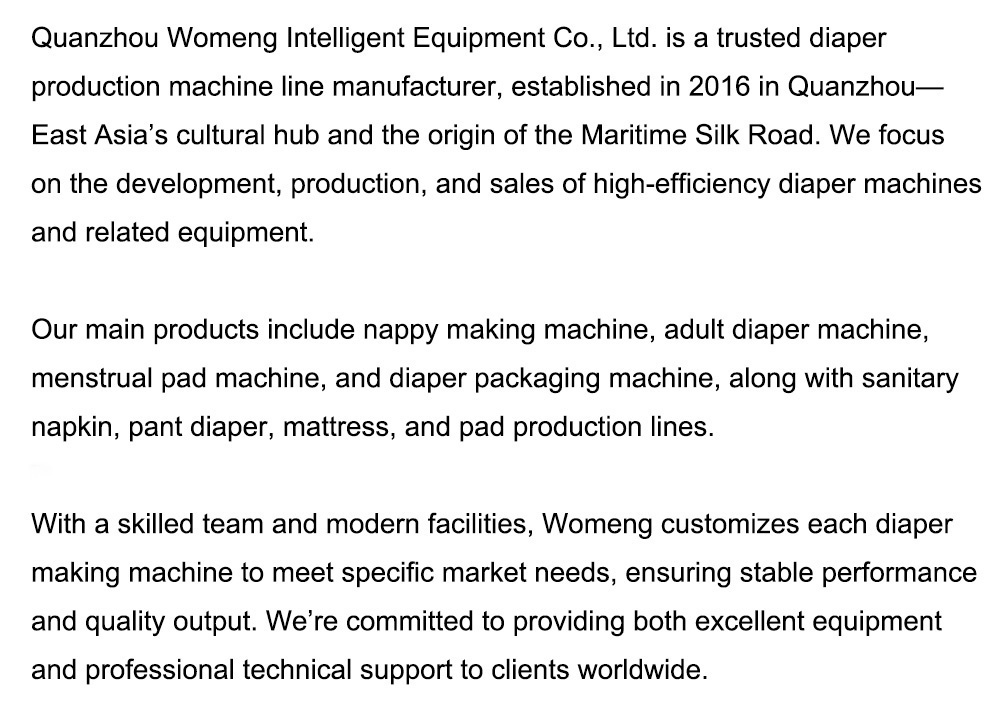

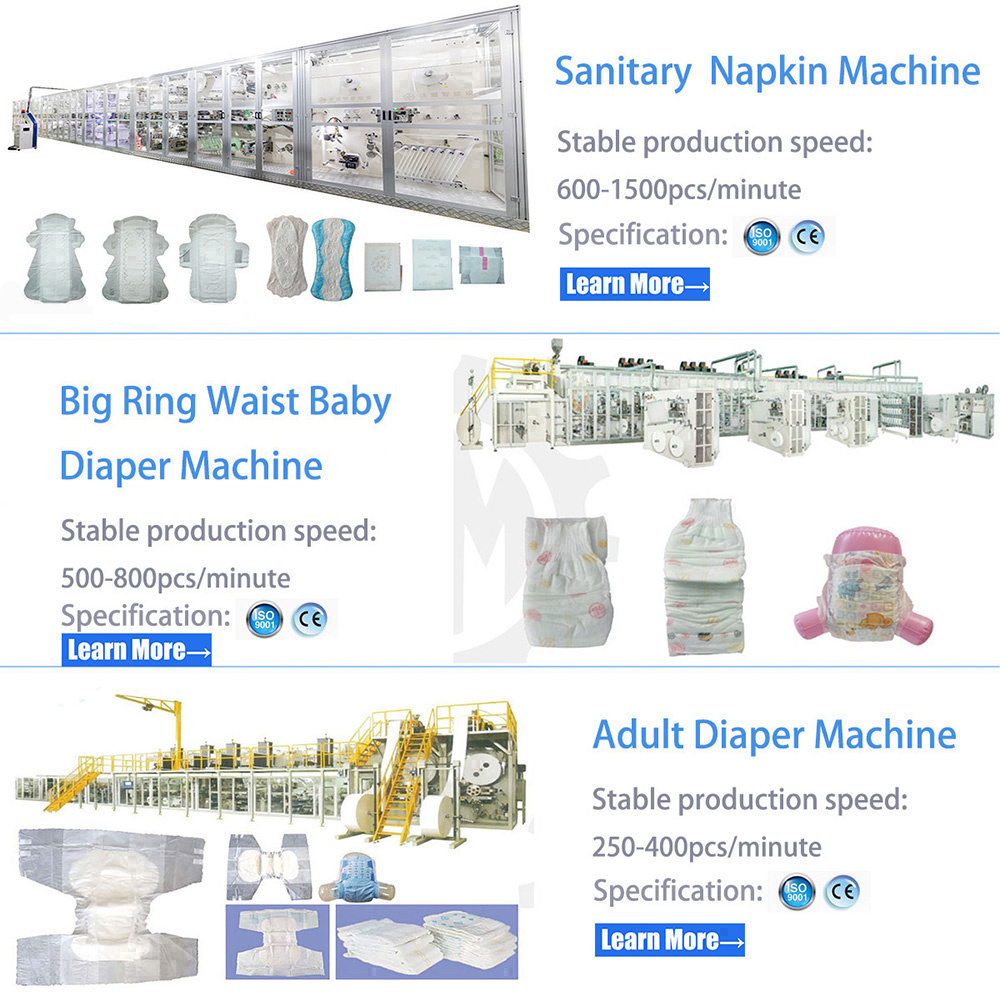

1)State-of-the-art technology

2)Fully customized solutions

3)Fast size change

4)Full lifecycle service and support

5)Full project managementLinear speed: Up to 300m/min for normal standard,Up to 400m/min for high speed

Prouduction speed: up to 600pcs/min for standard,up to 800pcs/min for high speed

Passing rate:>97%

| Condition | Brand New |

| Finished Product Size | S,M,L,XL(According to customers reqirement) |

| Production Line Size | 25x6x3M(For reference only) |

| Machine Weight | About 70 tons |

| Production Speed | 500-800Pcs/Min |

| Control System | PLC control system(Mitsubishi), HMI Operating on the LED touch screen, Configure HDTV monitor |

| Drive system | Servo Drive (Easy to change size), timing belt and flat belt are import products, and all the key parts are import bearings. |

| Production Efficiency | ≥97% |

| Machine Capacity | 400KW (Excluding glue machine and air compressor) |

| Power Supply | 3 Phase, 380V, 50Hz |

| Safety System | It has safety device on the operating side, matched with urgent stop switch.High audio fan uses sound insulation or silencer. |

| Machine Type | High Standar Full Servo |

| Product structure | Product structure: upper & lower tissue, cotton core (mix with SAP), cover sheet hydrophilic non-woven , ADL (Acquisitiondistribution layer) non-woven,leak guard hydrophobic non-woven back sheet,Waist band non-woven,color pattern sticker,elastic waist band, discarding sticker. |

| Packaging System | According to customer requirements with palletizer machine (double push double exit) adjustable |

| Warranty | 1 year |

Technical features:

* Compact design, easy operation & maintenance

* Modular design, for future upgrading

* Low consumption, high efficiency

* Servo or frequency inverter transmission

* Touch screen for man-machine conversation

* Auto record and calculation of process data

* Main raw material auto splicing at zero speed

* Inverter or servo unwinding with tension control

* Web guiding controller

* Sensor quality control systems

* Material broken and lost inspection, auto machine stops and defective products auto rejection

* Easy size changing and manufacture

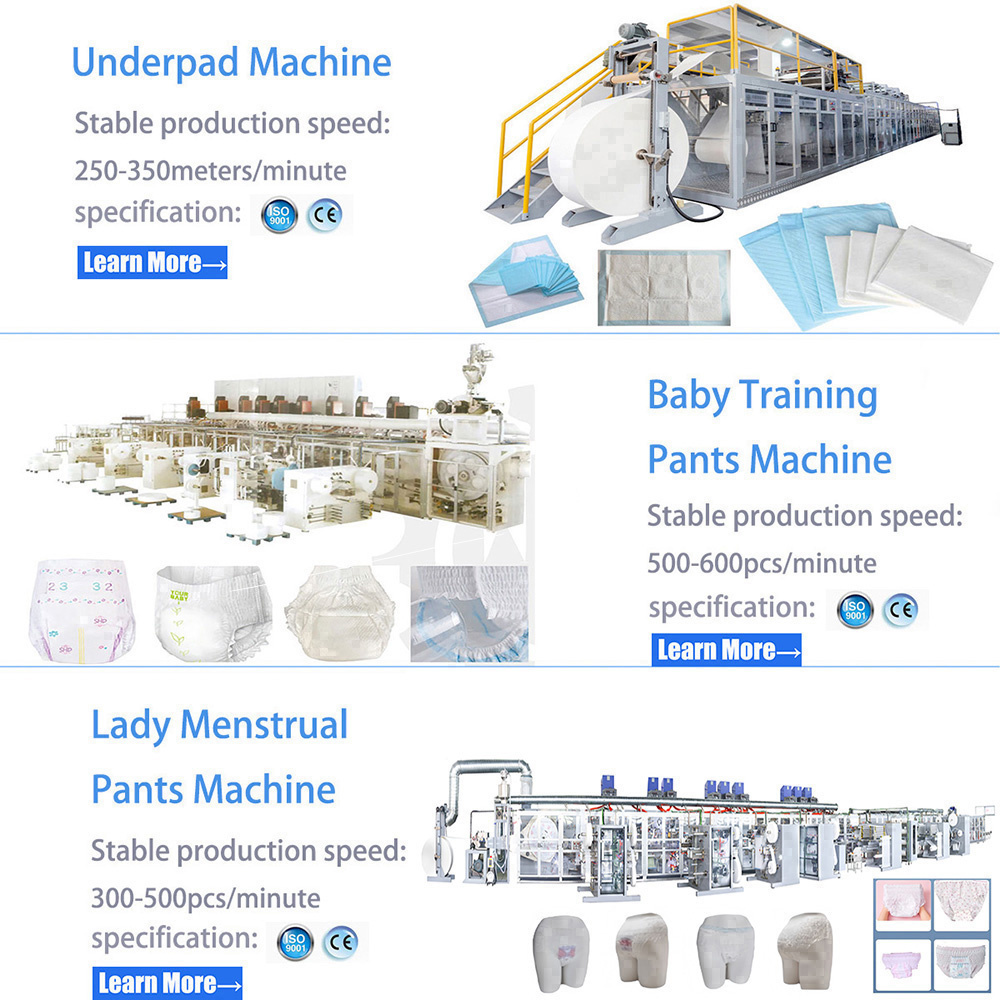

Machine Panoramic Image

High speed and high output + ultra-low loss, faster return on investment

The stable production capacity is 500 to 600 pieces per minute, and the high-end models can reach 700 to 800 pieces per minute, which is 40% to 50% higher than the traditional line.

Zero-speed material receiving and constant tension servo control result in a raw material loss rate as low as 1% to 2%, significantly reducing the costs of non-woven fabric, SAP, and wood pulp.

The servo system is powered on demand, saving 20% to 25% of electricity compared to ordinary motors. Only 3 to 4 people are needed for a single shift, significantly reducing labor costs.

Buyer value: The payback period has been shortened to 10 to 15 months, giving it a greater advantage in handling large orders.

Full-category flexible model transformation, covering all market demands with one line

Supports all sizes including NB/S/M/L/XL/XXL, and is compatible with regular diapers, long pants/cheer-up pants, thickened night wear, ultra-thin breathable and other styles.

Formula-based parameter storage, quick mold change within 10 to 15 minutes, no need for extensive mold replacement, suitable for multi-batch and small-order production.

Customizable umbilical protection incisions, three-dimensional concave core bodies, hot air surface layers, double diversion grooves and other regionalized processes.

Buyer value: Multi-functional in one device, reducing repetitive investment, and quickly adapting to the preferences of different markets such as Europe, America, Southeast Asia, and the Middle East.