Welcome to our websites!

Full Servo Baby Diaper Making Machine Production Line

| Main Parameter | |

| Overall Size | 30*6*4m |

| Machine Size | 22*2*3.5m |

| Design Speed | 600pcs/min |

| Stable work speed | 450-500pcs/min |

| Pass percentage | 98% |

| Power source | 380V,50HZ |

| Machine capacity | about 260kw |

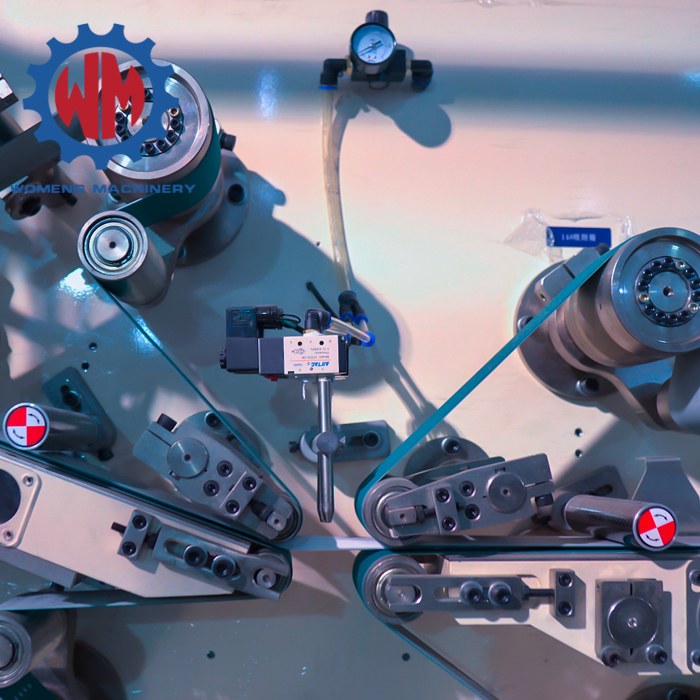

| Air pressure | 0.6-0.8Mpa |

| Machine weight | about 60T |

| Configuration | |

| Product size | S: 390×280 M: 450×320 L: 500×320 XL: 525×330 |

| Safety system | It has safety device on the operating side, matched with urgent stop switch.High audio fan uses sound insulation or silencer. |

| Control system | PLC control system,Operating on the touch screen,Configure HDTV monitor |

| Materials corrective system | Germany BST automatic web guide system (optional). |

| Drive system | Three-axis or full servo |

| Product structure | Up&Down Tissue, Fluff core(mix with SAP), ADL, Backsheet, Front tape, Topsheet, Leg cuff N.W., Side Tape, Waistband. |

| Tension system | Up&Down Tissue ADL, Back sheet, Top sheet, Cuff N. W., are adopt A&B shaft active unwinding by inverter motor. |

| Packing Way | Equipped with the stacker at the request of client. |

| Configuration | |

| Product size | 380×280 420×320 480×320 520×340 |

| Safety system | Safety guard installed at the operating side, with security identifier, emergency stop switch at per segment, Driven side is equipped with the radiator system and safety wire. |

| Control system | PLC control system,Operating on the touch screen,Configure HDTV monitor |

| Materials corrective system | Germany BST automatic web guide system (optional). |

| Drive system | Full servo drive, digital size change, ensure, run synchronized at full process. The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. |

| Product structure | Top(bottom) tissue paper,sap core,ADL,hydrophobic NW(leg cuff),topsheet NW,PE film,spandex,frontal tape,elastic nonwoven(zero-waste),S cut |

| Tension system | Tissue paper, cotton core (SAP), Top sheet nonwoven, ADL,PE film,back&wing release paper,packing film A&B shaft unwinding by Inverter motor |

| Packing Way | Auto stacker as customized design (one push two exit.). |

Write your message here and send it to us